installed today. Bearings were machined from a solid rod of delrin on our shop lathe. Also loaded a "forme" which contains a business form and our logo locked up and ready for printing. Now just waiting for a new drive pulley to replace the exisiting worn part and we'll be able to begin the print tests.

First Successful Motorized Test

Runs great and quiet! The 1915 patent 1/2 HP motor has plenty of power left! The clicking noise is the clip on the belt hitting the guard, still have to work on the alignment, but overall we are very pleased with the progress. We'll be adding guards, rollers and ink, should be ready for the first print tests right after Christmas.

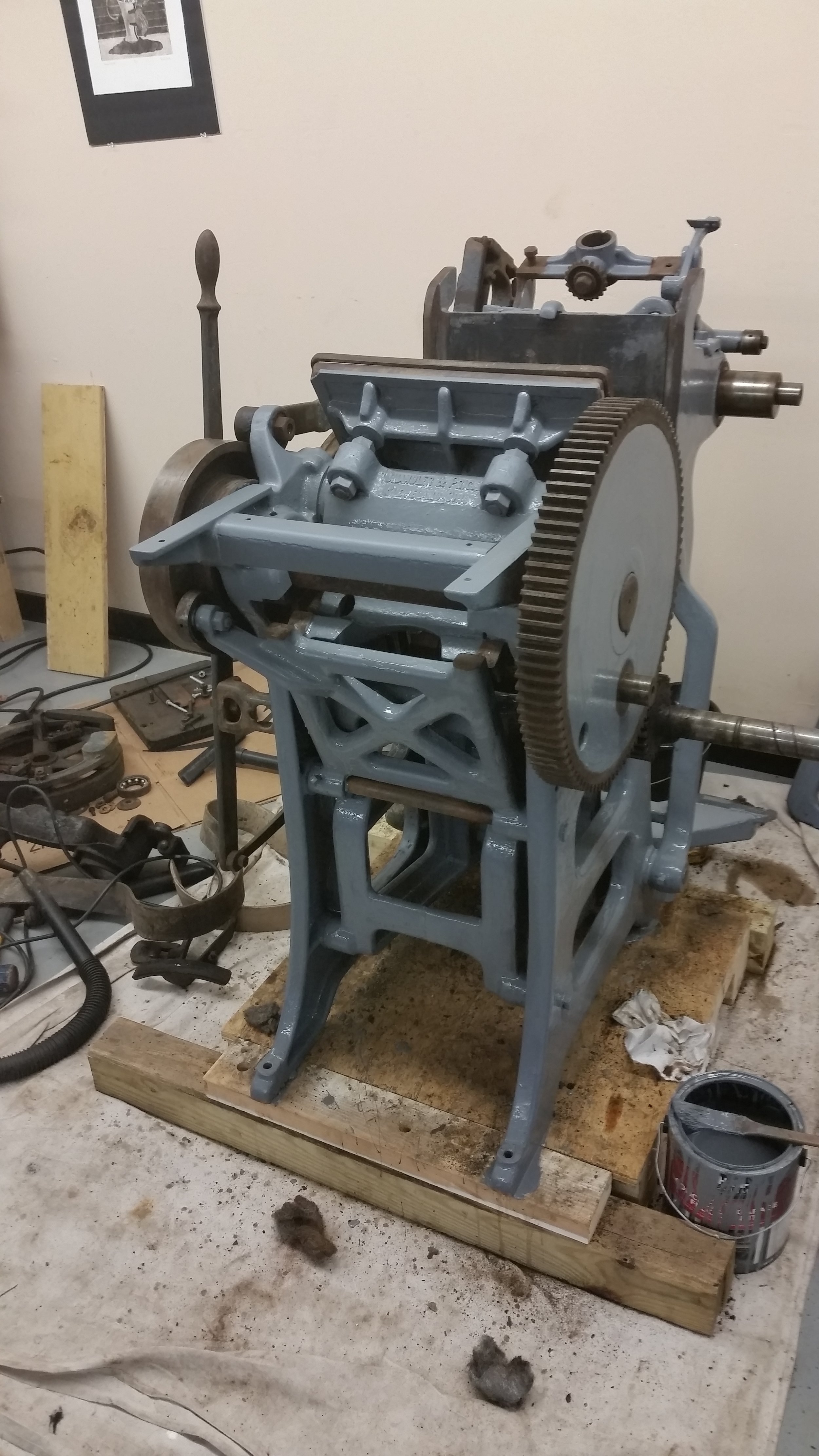

Frame is nearly complete

We've added the feed tables and finished painting the frame. We'll be making a guard for the gears and belts, which are too close to the operator for comfort. Also will be relocating the electrical control box under the feed table.

Now comes the testing! We've rotated the flywheel by hand and engaged the clutch regulator and brake. Everything seems to work. The old motor starts and runs like new, now that the brushes have been cleaned and the stator polished. Once we install the leather belt, we'll see how well everything actually works in real time!

Missing part found on Ebay!

The roller carriage back plate, a steel casting weighing about 9 lbs was one of the few missing press parts. After a quick search we found an exact replacement part on Ebay. Thankfully, by the early 20th century, manufacturing had already discovered the benefits of standardization. It was a perfect match!

An unusual power transmission

The 1915 Horton Pulley Regulator

Invented by Charles P. Strite of the Horton Company based in Minneapolis, Minnesota, the device was designed to allow the press motor to come up to speed without any load and then engage the press at a speed regulated by a system of counterbalanced clutch pads and a friction brake much like a car's drum brake. We're anxious to see it work!

The press frame is now painted. We chose battleship grey to match the original color of the press. Next step is to reassemble the press!

Type sorting is fun! Good thing we got good lighting in our new shop

This is how it's done. Dixie cups markers and magnifying glass. Anyone want to join the fun?

Reclaiming the type font from the dirt, much like archeologists!

Along with the press we found an old box with drawers and parts that had fallen through the rotten wood. We cleaned them and we are now starting to sort them. Looks like we have a good supply of both upper case and lower case 10pt font that we have yet to identify. There is also smaller font that will be a bear to sort! Also found a lot of "cast furniture." that is used to lockup the type as well as four chases

Beginning the restoration

The press is now in the shop, and we've succeeded in removing the flywheels, motor and other hardware. We've found that the press was built between 1911 and 1912 and that it had a single speed drive with a brake/clutch mechanism.

Success! How we did it...

Removing the motor, we first used a small winch and strategically placed boards to gently coax the press into the sunlight. [Slides]

Then we borrowed a crane that just happened to be demolishing the house next door to fly the press to a place we could load it onto a truck and take it to it's new life at the Red Onion Press [Slides]

Beginning the excavation

After careful examination of the shack's roof and walls we surmised that the best line of attack was to break out the wall and drag out the press using 2 x 6 boards as sleds.